Inventory management challenges for auto shop owners and how to overcome them

*This post was written by Roxanne Doche, Shop-Ware Marketing Director.

For years, auto repair shops have tried to invest wisely in getting the parts their technicians need – when they need them. However, it’s tricky to optimize inventory management without overspending on parts it could take years to use.

Afterall, how can anyone predict which types of vehicle will drive up to an auto repair shop? Once shops give up manual processes and trust the historical data within automotive shop software, it’s easier than you think.

Common inventory management challenges

Naturally, the usual challenges in inventory management have become even more difficult due to pandemic-related shutdowns. Just consider how 2020 changed the way auto shops do business.

To survive, shops are charging more money and focusing more on the value they offer to meet customer expectations. Therefore, having customers waiting for repairs undermines their ability to fix cars quickly and get them back on the road.

High-powered auto repair inventory management software tracks national and local suppliers and replaces inefficient processes of checking stock levels. As a result, better inventory management processes staff saves time, stress and human error. Ultimately, that translates into a better customer satisfaction.

1. Track automotive inventory storage better

Setting up proper supply chain processes and ensuring everyone follows them gets shops off to a great start for inventory management. Therefore, a shop management system that creates a smooth workflow makes it much easier.

When shops have large stock, poor use of storage space can lead to a range of problems. Just tracking and quickly finding parts can slow business growth. For starters, sort and place the most commonly used parts in warehouse space that is easy to reach.

Next, aim to align that system with modern shop managment software. Within Shop-Ware, shops can see the parts order status on each repair order. Simply view the order status on individual repairs to see what’s missing and order directly within auto repair inventory management software. That way, staff never overlook a part again.

Even better, parts statuses update live in real time, as repair orders evolve. Staff can visualize the part status across all repair orders in the shop or within an assigned group. As a result, they can respond quickly when needed and rest easy when parts flow in as required.

After that, they know when to dispatch jobs as ‘ready to start,’ which need parts, and which need immediate attention.

2. Get ahead of stock shortages

Running short on auto parts makes it more difficult for techs to keep working. Even worse, it can lead to conflict with service advisors who have to report delays to customers. There are multiple ways to manage customer expectations when the supply chain is slow.

Of course, the best option is the stay ahead of the problem. Advisors and parts managers can track stock-keeping units across the supply chain with auto repair inventory management software. Ideally, they will use automated inventory control to reorder parts before they run out.

While many automotive parts departments do physical inventory counts annually, that is unnecessary. Instead, checking stock more frequently via cloud-based automotive inventory management software ensures better accurate and better customer satisfaction. In the long run, it reduces the odds of running out of the parts that are needed most.

With Shop-Ware’s auto repair inventory management software, shops can automatically track parts on repair orders as:

- Not on premises or on the way

- On the way

- On premises

Next, stocked parts that are kept in inventory get sorted into:

- Below stock, not on the way

- On the way

- Stocked at proper level

This tracking happens for every single part on every single repair order. Shops can also preorder parts to speed up auto repair workflows, before even starting a repair order, which is a Shop-Ware exclusive.

3. Train front counter and warehouse staff to succeed

No school offers a course in auto repair inventory management. Instead, service advisors learn the job in the shop, usually starting with manual processes.

Some shops hire parts managers to specialize in certain makes and models. Yet, most shops count on a smaller team for managing inventory, among other roles.

While auto inventory management can seem simple, in reality, organizing, forecasting and keeping track of parts requires skill and expertise. For example, different software suppliers require users to type in the exact name of a part to get a match. Unless they know inventory data inside out, this can send staff on a time consuming scavenger hunt.

Shop owners could just show a new employee its inventory management solutions and expect them to learn the software alone. However, investing in training early pays off with more accurate inventory tracking and less stress for everyone.

Shop-Ware prides itself on making sure every team member knows how to use its shop management software support. Afterwards, its team is always ready to offer more advice as staff dive deeper and come up with new questions. Its automotive inventory management software goes one step further to make it easy to use.

4. Use technology to solve problems

Even the smartest parts manager cannot sort all the real time data that slows into a department in a day. Rather than trying to track inventory levels in a human brain, turn to an inventory management solution.

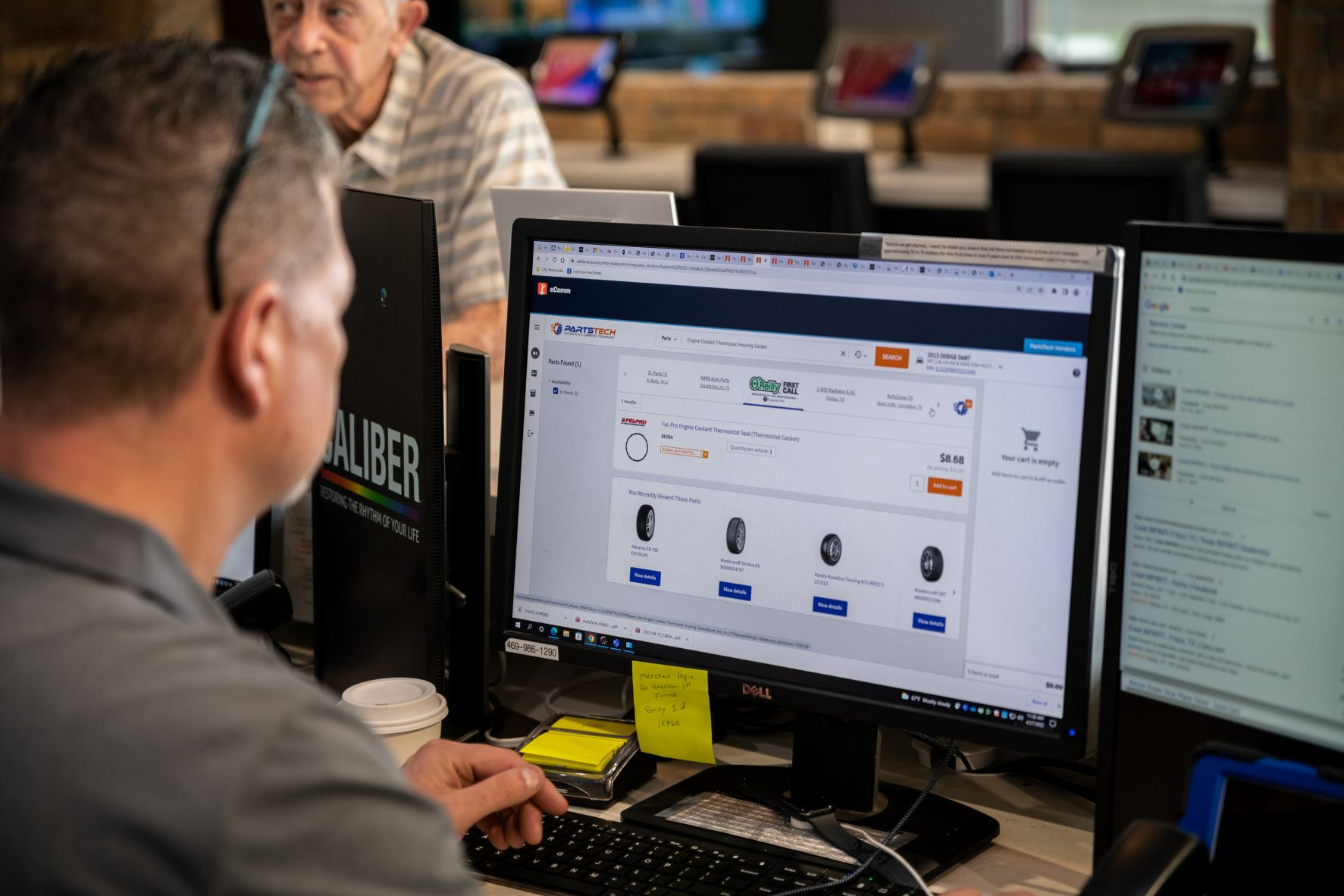

For example, give up sifting through several suppliers catalogs to find the right part. Instead, use Shop-Ware’s exclusive Native Parts Catalog for inventory tracking across multiple suppliers, comparing fit and price.

Likewise, stop guessing about why customers became annoyed about their service related to waiting for inventory. By checking sites like Google, shop staff can find and respond to negative reviews for auto shops. This gives customers answers and shows other drivers that a shop cares enough to follow up on a bad experience.

While these problems may seem insurmountable, there is an auto repair inventory management solution out there for shops. Finding the right partner with great tools allows shops to deal with supply chain disruptions and focus on fixing cars.

Transform your local business with revolutionary AI-powered software